Are You Choosing the Right End Mill for Milling Aluminum?

Posted by Cam Glass on 07.31.25

Unique Materials Call for Unique Solutions.

The Trouble with "Easy" Aluminum

Out of all the metals, composites, alloys, and other materials we encounter when machining, working with aluminum is typically known for being relatively straightforward. That is, unless you've spent time on the shop floor.

Chip welding, built-up edges, poor surface finish, and inconsistent tool life are problems that machinists are all too familiar with when their setup isn't perfectly dialed in when milling aluminum.

If you're taking the time to program and machine, it pays to get it right the first time.

Truthfully, the most crucial component of milling aluminum efficiently is always the cutter you choose.

I'm not just talking about making the call between a 2-flute end mill and a 4-flute end mill; I'm also discussing tool selection, down to the rake angle of the cutting edges.

It can be easy to overlook the small details in tool selection, but these same details can show up in your finish, your tool life, and your downtime.

This guide breaks down how to choose the right aluminum cutting tools, combining practical tips to improve chip control and surface finish with profitability and time savings. Whether you're slotting 6061 with a 2-flute end mill or profiling with a polished 3-flute end mill, you'll find insights here to help your tools support your business.

Why Aluminum Milling Isn't Always Easy

Aluminum is such an easy material to cut on paper. It's very soft, lightweight, easy to work with, and requires no particularly demanding stipulations when forming a workpiece.

This same softness presents as one of the main aluminum milling problems you'll encounter if you haven't precisely accounted for it.

Why? Since aluminum is as soft as it is, chip evacuation can often be a nightmare. Common issues found with aluminum chips, such as chip welding, heat retention, or built-up edges, can not only harm your surface finish but also age your tools faster than you can adjust your feed rate.

That's why successful aluminum milling is less about brute force and more about finesse. Proper chip control, flute geometry, tool selection, and speeds and feeds need to align like gears in a Swiss watch.

Suppose you're running cheap cutters or steel-rated end mills. In that case, you're more than likely bleeding time, money, and finish quality on every aluminum workpiece that passes through your doors.

Working with aluminum can be smooth and predictable, but only if your setup is dialed in.

3-Flute End Mills? 2-Flute vs. 4-Flute End Mills? What Matters and Why?

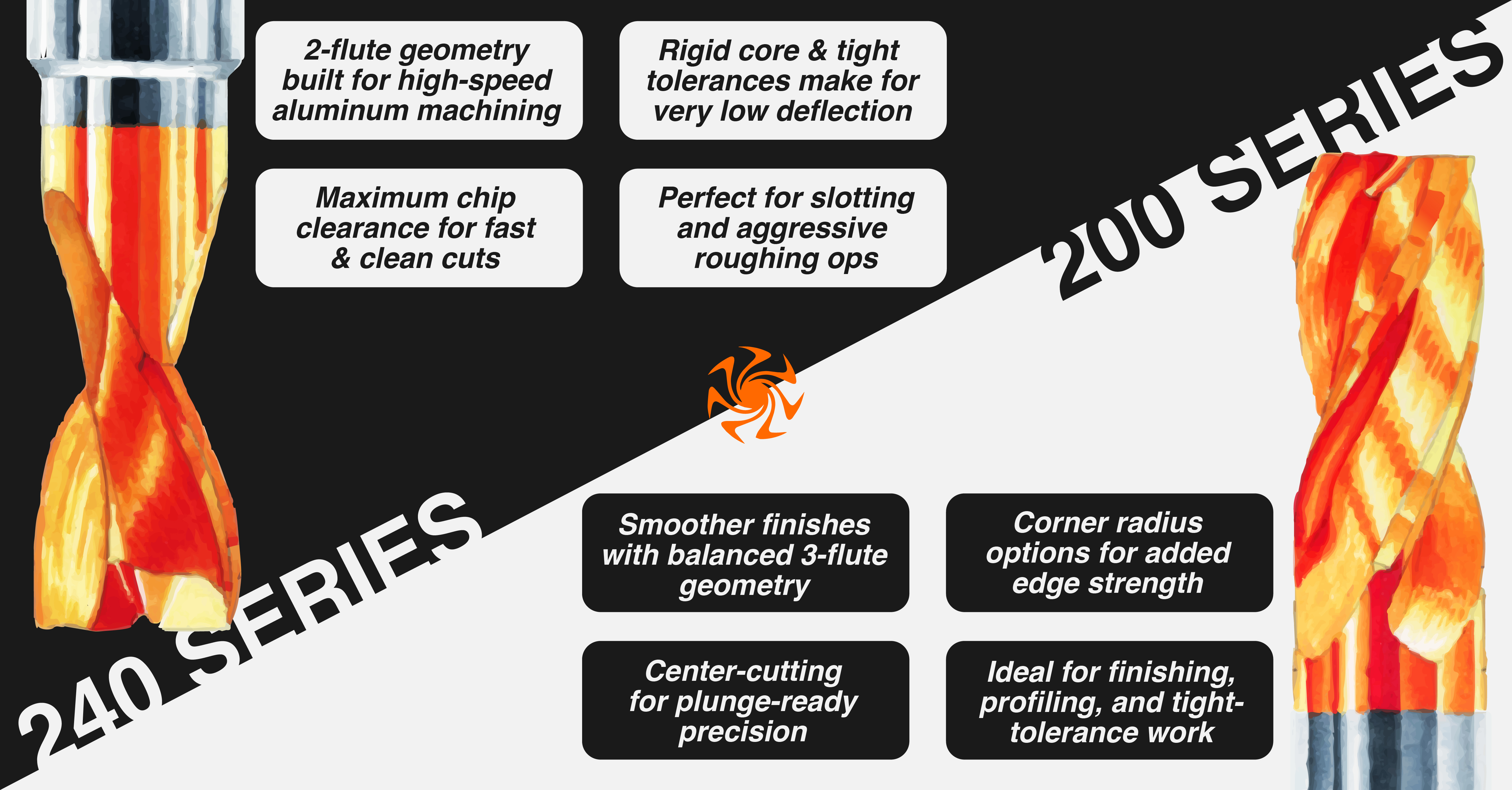

As you all know, flute count plays a crucial role in machining, but in the case of aluminum, the number of flutes on your cutter can make or break your results. It's key to understand the correlation between tool geometry and workpiece quality, considering the many variables that must be respected during the operation.

2-flute end mills offer maximum chip clearance due to their wide open nature, making them ideal for slotting and aggressive roughing. They leave plenty of space for the soft, stringy aluminum chips to efficiently and adequately evacuate the cut.

This is especially true when paired with high feed rates and limited coolant flow.

On the other hand, using a 3-flute end mill for milling aluminum can provide clean finishing cuts and a smooth surface finish by utilizing an extra cutting edge. While different in function from the 2-flute end mill, it's just as crucial for properly working through your op.

4-flute end mills , on the other hand, should generally be avoided in this scenario due to their tighter flute spacing compared to their counterparts. The tight flutes don't pair well with the stringy chips that milling aluminum produces, which can (and likely will) give you problems.

If you plan to use a 4-flute end mill, ensure it has a high helix angle and that it's sufficiently optimized for aluminum milling. These versions CAN outperform when it comes to finishing or profiling work, especially on rigid setups when paired with strong coolant or air blasts.

Geometry That Matters In Aluminum Cutting Tools

A cutting tool's geometric configuration is as vital as a car's engine. You wouldn't choose a 1.6L I4 to drop into your F-150 because it serves the wrong purpose. You also wouldn't choose a cutting tool with the wrong geometry for the same reasons.

Like engine swapping in your pickup, selecting the correct geometry will make or break performance. When chips aren't adequately cleared or the cutting edge rubs rather than shears, not only will you feel it on the workpiece, but you'll feel it in the wasted hours, broken tools, and bottom line.

Here's what geometry factors matter when cutting aluminum:

High helix angle (45 or higher): Increases shearing action and helps efficiently route chips away from the cut.

Polished flutes: Reduce chip adhesion while simultaneously improving evacuation rates

Generously sized flutes: prevent buildup and allow for heavier removal

Corner radius: Strengthens the cutting edge to reduce chipping and premature wear, especially helpful in aggressive aluminum operations.

Large core diameter: adds rigidity to the tool and assists with resisting deflection

When all of these features are in play, they combine to deliver smoother cuts, cleaner finishes, longer tool life, and generally keep headaches at bay. If your aluminum end mill lacks these, even simple jobs have the potential to turn into nightmares.

These features are the most common that are engineered into tools built specifically for aluminum milling, like Sonic Tools' 240 Series 2-flute end mill for high speed machining.

With optimized flute geometry and chip evacuation, it's designed to simplify high-speed aluminum work, even in challenging setups.

Click here to visit soniclp.com and read more about our 240 Series selection.

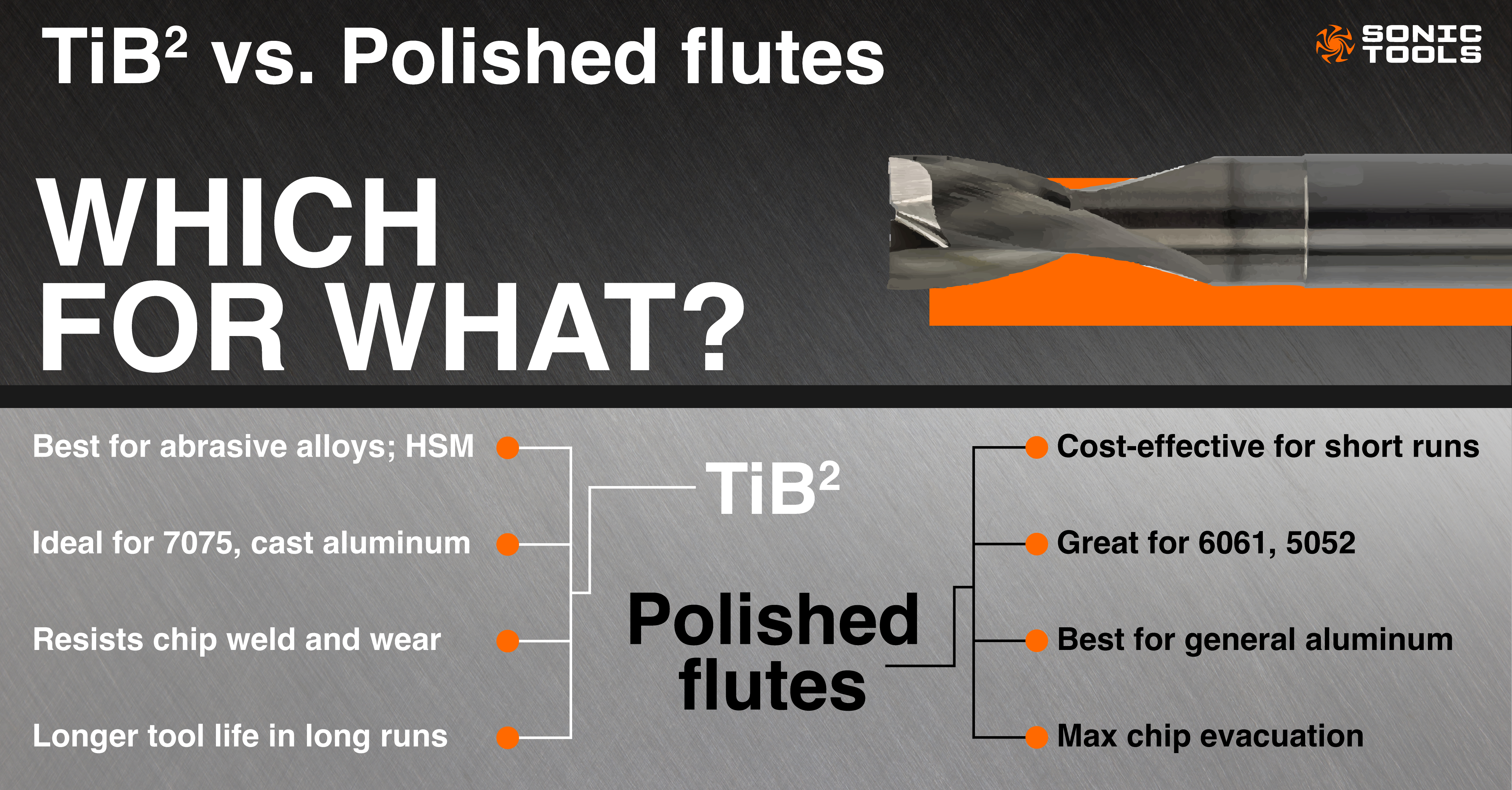

Coated or Uncoated? How Are You Treating Your Aluminum Cutting Tools?

When you're milling steel or titanium, using a coated tool is a no-brainer. It just makes sense. However, when you're milling aluminum, making the call on a coated tool is a nuanced decision. Depending on which coating the tool has, it could completely backfire and cause the same issues you'd thought you were fixing.

Uncoated carbide and polished flutes. This combination is the bread and butter for aluminum cutting tools. It minimizes friction, keeps those chips efficiently gliding away from the cut, and reduces the chances of any chip welding or buildup near your cutting edge.

That being said, there are certainly coatings available that have become commonplace for working with aluminum. One coating we offer for our aluminum end mill is TiB2, or Titanium Diboride. This coating offers:

- Better wear resistance in HSM

- Lower coefficient of friction

- strong protection when cutting abrasive grades like 7075 or cast aluminum

Additionally, ensure that you avoid general-purpose steel coatings, such as AlTiN or TiAlSiN, when working with aluminum. These coatings help to retain heat, which, in the case of soft and stringy chips, significantly increases chip welding and edge buildup.

Bottom line: If your shop's running aluminum quickly, hot, or in large quantities, aluminum-specific coatings are worth considering. Otherwise, polished carbide typically handles the load fine.

5 Common Problems in Aluminum Milling (and How to Fix Them)

Aluminum is quite soft, but it's hard to deal with when your setup is flawed. Here are some of the more common issues that shops run into when milling aluminum, and what you can do to mitigate them:

| Problem | Fix |

| Chip Welding | Use polished tools or ZrN coating, reduce heat, and improve chip evacuation |

| Poor surface finish | Increase RPM, use 3-flute tools, reduce tool wear, and stabilize setup |

| Chatter | Shorten tool stickout, improve rigidity, and optimize feed/speed ratio |

| Chip packing | Switch to a lower flute count, increase air blast, or coolant flow |

| Built-up edge (BUE) | Lower feed per tooth, use polished tools, avoid heat-holding coatings |

Most of these problems stem from issues with heat management, chip control, or incorrect tool geometry. Once these issues are diagnosed and addressed, milling aluminum becomes one of the most efficient operations you'll undertake.

What Should You Prioritize? Tool Life, Speed, or Finish?

At this point, you can see that aluminum has a personality of its own when compared to the other materials. When aluminum problems arise, we know they often come down to two things: the tool and its run.

This dilemma presents a balancing act: above all else, do we prioritize extending the tool's life, maximizing output, or achieving finished quality? This answer depends on you, but it also depends on the part, the material, and what matters most for that specific job.

If you're running high volumes , prioritize speed. Use a 3-flute end mill, a high helix, polished flute, or a coated, solid carbide end mill. Run these tools efficiently, keep the chips clear, and complete the job quickly, even if it means replacing tools a bit sooner than you'd prefer.

If you're aiming for the best possible surface finish , be sure to adjust the feed rate slightly and let the tool's geometry take over. A correctly coated or polished fluted tool will reduce chip adhesion and achieve a mirror finish right off the machine.

If the job is a one-off or highly toleranced , consistency is key. Make sure to take your time dialing in your settings. You're shooting for exact accuracy down to the micron, and you'll need to be as precise as possible. Speed can hinder this accuracy.

Tool life is important, but it's not the only factor worth prioritizing on the job.

For more info about aluminum-specific milling techniques and processes, click here .

Make Your Tools Work for You

Aluminum is one of the easier materials to work with, but it can and will punish you if you make mistakes. If you're fighting chatter, chip weld, or poor finish, don't blame aluminum; recheck your setup.

Quick Recap :

- Use 2-flute end mills for aggressive slotting and maximum chip evacuation

- Choose a 3-flute end mill for faster throughput and clean surface finishes

- Avoid standard 4-flute end mills unless they're specifically optimized for aluminum milling

- Prioritize polished flutes, a high helix angle, and generous core geometry when choosing your end mill

- Consider TiB2-coated tools when running abrasive alloys at high speeds

- Dial in your feed rates, tool stickout, and cooling methods to avoid chip weld and finish issues

Getting these things right can make milling aluminum a fast and repeatable win. If you're looking for more repeatable wins, we've got you covered.

Sonic Tools offers high-quality, competitively priced solid carbide end mills designed for various machining styles, including both standard and custom solutions. If you need it, Sonic Tools can make it.

Visit soniclp.com to explore our aluminum cutting tools or start your custom quote today. If you're ready to get started on a custom solution inquiry , click here !

Optimization begins at the tool. Better tools, better results.