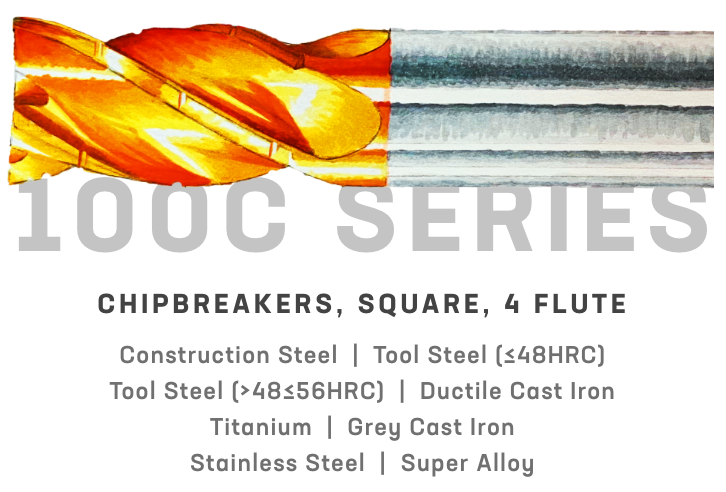

100 & 200 Series

We have compiled our 25 years of experience and comprehensive testing and design to bring forward a line of high-performance cutting tools.

In this section, we took our most successful combinations of rake, helix, core, balance, and accuracy and applied it to several series of broad spectrum use end mills for ferrous and nonferrous materials. All of the items in this section are stocked coated, but uncoated items may be available for rapid delivery upon request.

Section Features:

- ✓ Center cutting geometry for ramping and plunging operations

- ✓ Balanced design reduces system resonance and tool chatter improving tool life, spindle life, and surface finish

- ✓ All shanks finish ground to h6 tolerance for use in precision tool holders

- ✓ Shank finish is not polished to aid in slip resistance

- ✓ Every item is lot tracked with engraving that has been optimized for readability and to eliminate tool holder interference

- ✓ Weldon flats are available upon request. Weldon flats are not recommended or included as a standard option due to a potential increase in TIR

- ✓ Diamond coating available upon request